From stock chaos to profit: 6 salon inventory case studies

Every minute, salons across North America throw out 877 lb of beauty waste — leftover color, used foil, half-empty hairspray cans. That’s 421,000 lb a day — enough to fill ten garbage trucks before you finish this paragraph.

But this isn’t just an environmental problem. It’s money — your money — sitting on store shelves, locked up in overstock, or disappearing in last-minute supplier runs across your internal supply chain. All those “just-in-case” orders and dusty slow movers quietly drain profit faster than a blow-dryer on full heat. For many businesses, the bigger concern isn’t buying; it’s how to manage and control what’s already on hand.

In this case study inventory management roundup, you’ll see six real-world stories of salons that turned their back rooms into profit engines. Each case study shows a simple, repeatable set of inventory management practices — from a $20 kitchen scale to clear reorder rules inside modern inventory management systems. Over the past few years these moves have been adopted by companies of all sizes, not just salons or retail stores. They’re steps you can start managing tomorrow, whether you run a 3-chair studio or multiple locations.

Case 1: Salon 718

Size & Location: Brooklyn, NY, USA — 5 locations

Source: Phorest

This fast-growing chain hit the usual chaos: counts lagged, shipments were late, and managers lost hours reconciling what each site actually had. Shelves told one story, spreadsheets another, and employees were stuck in endless group chats. They needed an efficient, phone-first inventory management solution to count instantly, standardize naming, and centralize purchase orders so the company’s operations moved in sync.

Before

- Manual inventory tracking with spreadsheets led to errors and drift.

- “Are we in stock?” depended on texts between locations.

- Duplicate buys tied up cash and hurt the balance sheet.

Tactics & tools

- Scanned inventory items with barcodes: managers used a mobile app during open/close — fewer errors, no clipboards.

- Forecasted customer demand & set low-stock alerts: the system flagged reorders before shelves went bare.

- Centralized purchase orders in one computer system: one source of truth for on-order, received, and variances.

Results

- Faster, cleaner counts across all locations (healthier inventory levels).

- Fewer “we’re out” moments and smoother reorders.

- No duplicate purchases — more working capital freed for investment.

Steal-this-playbook

- Use your phone for counts — a lightweight inventory management software app with barcode scanning reduces user error instantly.

- Set reorder points per item — start with ~two weeks of expected use so you prevent stockouts without overbuying.

- Standardize product names — one clear format (“Brand – Line – Shade/Size”) makes reports and transfers sane.

- Centralize purchase orders — keep approvals and receipts in one place. Not sure which tools cover multi-site, scanning, and POs? See Best salon inventory management software & apps (2025): pricing, pros & cons

Case 2: PURE Medical Spa

Size & Location: Idaho, USA — 3 locations

Source: Zenoti

PURE wanted every treatment room ready, every time. But reality disagreed: one site ran out midweek while another had boxes stored in the back. Promotions in one place didn’t match what customers wanted elsewhere, and leadership often learned about shortages when a client was already in the chair. Real-time monitoring tied to sales and usage gave them the visibility to balance supplies between locations, manage reorders, and stop guessing.

Before

- Each site tracked differently, so data didn’t line up.

- No single dashboard for inventory levels, sales, or shipment status.

- Buying was reactive — not based on trends.

Tactics & tools

- Centralized multi-location platform — standardized procedures from booking to inventory control.

- Unified dashboards for stock and sales — every manager looked at the same numbers.

- Data-based purchasing — orders matched actual use patterns, cutting costs and waste.

Results

- Consistent data across the company.

- Orders aligned with needs, not guesses.

- Easier to manage the company’s operations from one place.

Steal-this-playbook

- Adopt one platform for all locations — a single system simplifies managing bookings, marketing, and supply control.

- Use real-time views — give managers live stock levels and movement to spot slow movers early.

- Order from the last 30–90 days of usage — base purchases on reality, not instinct.

- Standardize your processes — one set of rules for naming, counting, and reorder points. For a step-by-step framework, read Salon inventory management: a guide to a successful business.

Case 3: Salon Thirty-One

Size & Location: Alabama, USA — 2+ locations (growing chain)

Source: Vish

A simple but costly blind spot: flat-rate color pricing — even when long-hair clients used far more product. Stylists mixed extra “just in case,” and margins evaporated. The fix was a usage-based billing model integrated with the POS so customers paid for exactly what they used — and stylists were rewarded for precision.

Before

- Flat pricing hid real product costs.

- Over-mixing was routine.

- Long-hair clients quietly eroded profits.

Tactics & tools

- Charged per gram of dye — base price covers a standard amount (e.g., 40 g), with a per-gram surcharge beyond that.

- Weighing + checkout integration — grams recorded at the bowl flowed to the front desk automatically.

- Incentives for efficient mixing — bonuses for keeping waste under a target.

Results

- +$120,000 extra color revenue in year one.

- Lower cost as a share of service sales.

- Transparent pricing improved customer trust and stylist morale.

Steal-this-playbook

- Publish a base-plus-per-gram menu so customers understand the math.

- Record usage directly in your system so the front-desk users don’t re-enter anything.

- Reward low waste — small bonuses keep habits aligned with margin goals.

- Show real examples on reception screens or social media to normalize the approach.

Case 4: Elegance Salon & Spa

Size & Location: Bloomfield, USA

Source: NinjaSuites

Shelves looked organized, but bestsellers were missing while slow movers took prime space. Capital was locked in items that didn’t move, and weekly emergency supplier runs became routine.

Before

- Overstocked slow items; fast movers constantly short.

- Cash tied up in unused inventories.

- Manual processes created errors and rework.

Tactics & tools

- Reviewed recent sales to set min/max — used built-in reporting to set realistic stock levels.

- ABC grouping by speed — categories based on movement guided promos and clearance plans.

- Negotiated with suppliers using hard numbers — smaller shipments and better terms.

- FIFO rotation — alerts pushed older lots forward to cut expiry waste.

Results

- Excess inventory down 35%.

- $1,800/quarter saved in holding costs.

- Retail revenue up 15% as customers found what they wanted.

Steal-this-playbook

- List your top inventory items from the last 90 days (POS or booking app).

- Set min/max — keep ~2 weeks of fast movers; give slower lines a tighter cap.

- Clear anything unsold for 120 days via bundles or BOGO to recover cash.

- Negotiate with data — ask for smaller cases or 30-day terms. For more cost-saving tactics, see Cut inventory costs in salon: save on salon inventory & optimize stock.

Case 5: Capizzi MD Plastic Surgery & Med Spa

Size & Location: Charlotte, NC, USA — 2 offices

Source: PatientNow

Injectables and medical-grade skincare moved fast, but counts lived in paper charts, retail sales in another system, and no one knew which lots expired next. They connected clinical charting directly to inventory so documentation adjusted on-hand units automatically — with lot/expiration tracking and reorder reminders.

Before

- Manual charting caused drift between usage and counts.

- No single place to see what sold, what was used, and what would expire.

- Inconsistent dosing undermined retention.

Tactics & tools

- Chart-to-inventory sync — documenting a treatment deducted units; no double entry.

- Lot & expiry controls — daily/weekly views surfaced upcoming expirations.

- Unified sales + usage reporting — orders matched reality.

- Consistency = trust — saved treatment templates improved repeat visits.

Results

- Cleaner counts and fewer expiry surprises.

- Less admin, more chair-time.

- Higher repeat bookings thanks to documented, reproducible outcomes.

Steal-this-playbook

- Connect charting to supply control — pick an EMR + inventory combo where documentation deducts units automatically.

- Turn on lot + expiry discipline — record lot numbers on receipt and review “soon to expire” weekly. For more savings ideas, see Salon inventory tips: how to find hidden savings.

- Standardize templates so reports are comparable across providers.

- Order from real usage — analyze the last 30–90 days of administered units plus retail sales and set min/max per SKU.

Case 6: Coveted Salon

Size & Location: Saskatoon, Canada — 3 chairs

Source: SalonScale

Product costs ate margins because stylists guessed color amounts and pricing was flat. They switched to parts-and-labor without heavy software.

Before

- Guess-and-pour mixing.

- Stylists absorbed product costs.

- Flat rates hid usage differences.

Tactics & tools

- Weighed every drop with a basic $20–$30 scale; grams logged in a simple sheet or free app.

- Charged for what was used — bill showed dye cost plus time.

- Bonused precision — small rewards for low waste.

- Made waste visible — a break-room board created friendly competition.

Results

- Color waste down ~42% in three months.

- Service profit per hour up 19%.

- A clearer revenue picture and happier clients.

Steal-this-playbook

- Pick one service and measure for 30 days; record grams in a sheet.

- Find your average use and set a base to cover it; charge per extra gram.

- Show the math to the team — tiny waste multiplied by clients = real money.

- Celebrate precision with gift cards or time off.

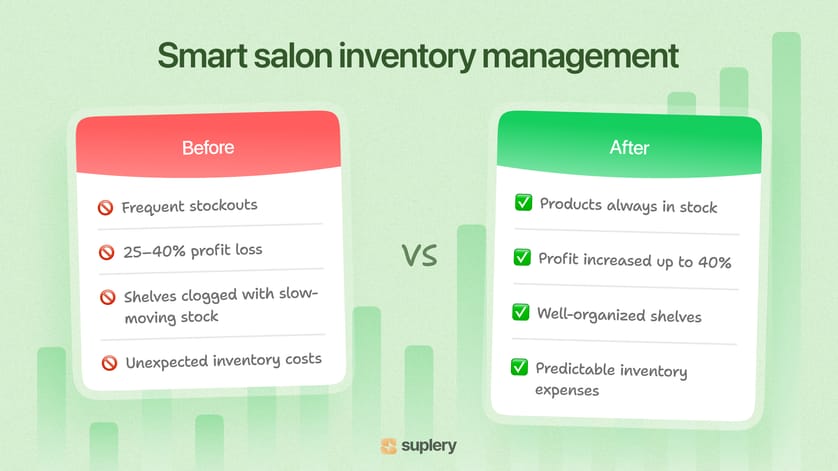

How Supplery turns these wins into plug-and-play reality

Think back to the wins you just read about: a stylist in Saskatoon trimming color waste with a $20 scale, a Brooklyn chain scanning barcodes instead of chasing spreadsheets, a med spa that never misses an expiry date. Now picture those best moves living inside one simple screen.

Instead of weighing tubes, scribbling grams, then checking a separate order sheet, Supplery does it at once: scan a barcode and the system logs usage, updates on-hand inventory levels, and suggests when to reorder. If you run multiple locations like PURE, you see every shelf in real time — no Friday supply runs, no “Who’s got extra shampoo?” calls. You can assign user roles, keep procedures consistent, and rely on stored data rather than memory. If a manufacturer changes pack sizes or a shipment is delayed, you still keep control.

It’s not a different playbook — it’s the same tactics from these case studies, stitched together in one inventory management solution so they run automatically. The result: a more efficient process with the capabilities to manage day-to-day without panic.

Spin up Suplery today

Get real-time shelf tracking, automated reorders, and multi-location control — so you cut waste, save hours, and keep every chair revenue-ready.

Try Suplery nowThe 7-step master checklist — your path from chaos to control

These seven steps are the through-line behind every win above. They work in a notebook, a Google Sheet, or in Supplery — the only difference is how much of it runs itself.

- Count what matters first — Like [salon] 718, start with your top movers, not the whole shelf.

- Sort by speed — Use Elegance’s fast/slow/no-go tags to decide what to check weekly, bi-weekly, or monthly.

- Set clear stock levels — PURE’s min/max rules kept branches aligned without overbuying.

- Show the waste — Coveted’s board (or Supplery’s usage report) makes waste visible and competitive.

- Link money to smart habits — Salon Thirty-One tied accurate mixing to stylist bonuses.

- Hold quick weekly team chats — a 15-minute Monday huddle aligns promos, transfers, and reorders across sites.

- Automate when ready — Capizzi MD’s chart-to-inventory sync shows how manual steps can be implemented right in the daily workflow.

Follow this path and you’ll see the same shift our case studies delivered: fewer stockouts, lower waste, and more cash freed from your shelves.

The latest articles and industry insights delivered to your inbox

The latest articles and industry insights delivered to your inbox

Subscribe to receive a monthly digest of our most valuable resources like blog posts, whitepapers, and guides.

Oh no! We couldn’t subscribe you ☹️

Done! You've subscribed 💛

Unsubscribe anytime. Your data is stored for business-to-business communication purposes. See our Privacy policy.

Frequently asked questions

Is this really a study inventory management piece or just stories? It’s both: a practical case study inventory management roundup plus a playbook of practices you can implement today.

What is salon inventory management, in one line? It’s how you manage and control supplies so the right items are available at the right time — with standard procedures for counting, reordering, and valuing what you carry.

Do I need software or can I stay manual? Manual works for very small setups, but most businesses grow out of it quickly. Once SKUs climb or you add locations, an inventory management system reduces errors, keeps a single source of data, and lets you manage reorders efficiently.

Who should own this day to day? One person should be accountable, but everyone contributes counts. Train employees on simple procedures, then add permissions so managers can approve orders while front-desk users handle cycle counts.

How do I set stock levels the first time? Use recent sales and service usage, plus lead time from each supplier. Start with ~two weeks on hand for backbar; retail turns faster. Revisit monthly as you learn.

How does this touch finance and the balance sheet? Inventory is a current asset. Bloated levels trap cash that could fund marketing, staffing, or equipment investment, while leaner levels improve profits and cash flow.

What about shipment delays and distribution partners? Track promised arrival dates and keep lead times per supplier. If you buy through a distribution center, compare case-pack discounts to carrying costs so you don’t overload storerooms.

Do brands and manufacturers matter in reports? Yes — track by brand and manufacturer so you can compare quality, backorders, and promo impact across lines. If one manufacturer changes pack sizes, adjust min/max and avoid overbuying.

Can systems help separate finished goods and backbar? Good software separates retail finished goods from service consumption so your reports show true retail margins and service costs.

We have multiple locations — what changes? Centralize purchasing, standardize naming, and keep one dashboard. Managing transfers before buying more is usually the fastest win for companies with more than one site.

What are the must-watch KPIs each week? Inventory turnover, stockout incidents, waste %, product cost as a % of service revenue, and cycle-count compliance. Add a quick review of orders awaiting shipment.

How do I start if everything is a mess? Begin with one category (color, foils). Create a simple naming standard, migrate counts into one system, and run a short parallel period. Build a small SOP you can say you developed in-house, then expand it category by category.

Can this improve the customer experience? Absolutely. Reliable availability, consistent pricing, and fewer “we’re out” moments keep customers happy and returning — which shows up directly in sales.

Where is all that data stored and who sees it? Cloud systems keep counts, purchase orders, and expiry logs stored centrally. Set user roles to control who can edit, approve, or view.

Last updated on Aug 14, 2025

This is a brand-new article featuring the latest real-world salon case studies on inventory management. Explore fresh, actionable insights from top salons that successfully optimized their stock and boosted profits.

Please share this post

Table of Contents

Case 1: Salon 718Case 2: PURE Medical SpaCase 3: Salon Thirty-OneCase 4: Elegance Salon & SpaCase 5: Capizzi MD Plastic Surgery & Med SpaCase 6: Coveted SalonHow Supplery turns these wins into plug-and-play realityThe 7-step master checklist — your path from chaos to controlFrequently asked questionsReorder point vs PAR level: the logic behind salon inventory control

Most salons don’t run out of products by accident — they run out by guessing. This guide explains how reorder points and PAR levels actually work, and how to stop inventory chaos for good.

Inventory management in beauty business

8 min

Best salon inventory management software (2026): pricing, pros & cons

Discover the ultimate salon inventory software guide for 2026. Compare top platforms, reduce product waste, boost profits, and learn how leading salons effectively choose and implement inventory solutions.

Inventory management in beauty business

10 min

Inventory control differences across salons, spas, and barbershops

Inventory control isn’t glamorous, but it makes or breaks beauty businesses. This article reveals the differences in salon, spa, nail, barbershop, and medspa inventory management — and shows how to cut waste while boosting profit.

Inventory management in beauty business

10 min

Unlock FREE bonus material!

Get your hands on "Salon order planner by Suplery". Subscribe to our newsletter and receive a link to download it straight to your inbox.

Oh no! We couldn’t subscribe you ☹️

Done! We've sent a link to your Email 📨

Trusted by the best in the beauty industry.

Transform your beauty business with Suplery!

Already enjoying our expert tips? Take the next step and join Suplery to revolutionize your business operations.

Huge range of professional products

One-click checkout after first order

Automated predictive orders

Seamless inventory management

From words to action

Start working with Suplery and explore all the tools and services you need to expand your business

Get started with Suplery24/7 Support

Secure payments

Designed by industry’s experts