Salon inventory tips: how to find hidden savings

Any service company uses materials in its operations. In the beauty business, we spend 10% to 25% of the revenue or even more on products and materials. Do you ever think that the inventory in stock is a substantial amount of money frozen in products stored in your warehouse? You can not use them to cover your business cost or just spend them.

While it is essential to have inventory on hand to support your business operations, having too much of it ties up cash and results in high costs, and low levels cause stockouts and lost sales. Obviously, we must find the sweet spot — the optimal balance between having enough inventory to meet demand and keeping inventory costs low.

This article will explore how you can uncover hidden savings in your inventory management and maximize your return on investment (ROI). This metric, which measures the profitability and efficiency of an investment or business initiative, is critical to assessing the success and viability of projects and making informed business decisions.

What hidden savings are

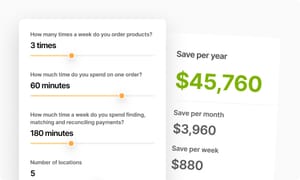

To illustrate this idea, let's look at a simple example. Imagine a beauty salon owner who spent $30,000 on inventory. Every week, an extra $5,000 is required to support operations. However, if the salon could operate efficiently with only $20,000 invested in initial stock, the difference of $10,000 would be cash in the bank account, with nothing else changing. That's the idea — you can generate cash by reducing your inventory investment without changing anything else.

You can easily find out what your potential savings are with our free Savings calculator.

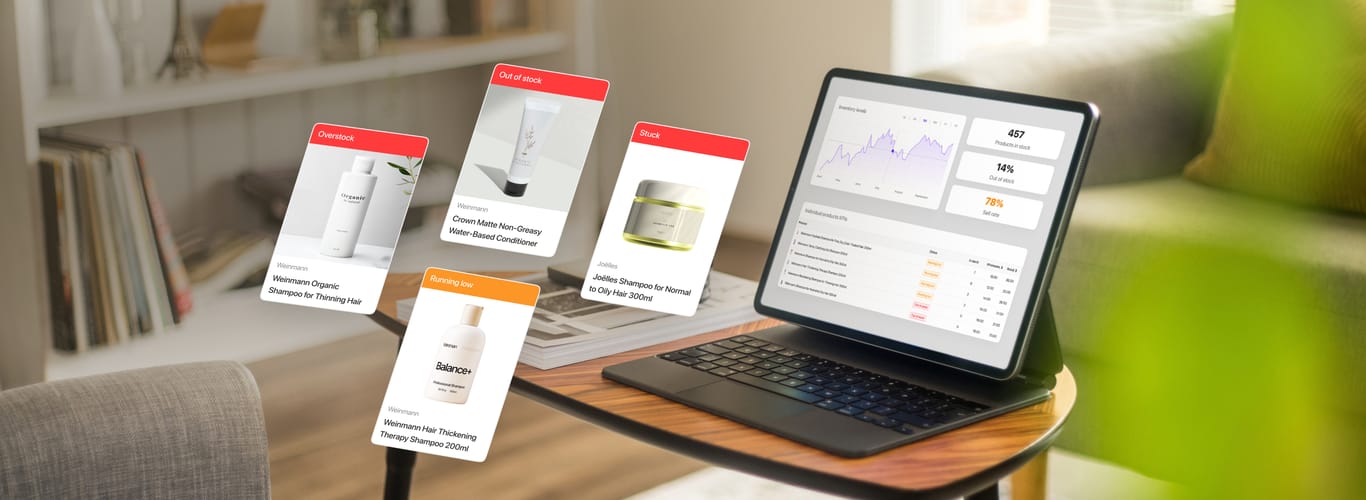

Hidden savings is something that appears when your inventory strategy is weak. And the key to resolving this problem is moving from tactical, reactive decision-making to a proactive, data-driven approach focused on maximizing efficiency and minimizing costs. Even though it might be a tough job without special software, I will explain the whole process in a way that helps you to implement the new approach in your business.

Skyrocket your salon’s profits!

Struggling to boost revenue? Our 50 service ideas PDF is packed with creative, high-impact services to fill your salon’s schedule — bank account. Download now to start earning more!

Oh no! We couldn’t subscribe you ☹️

Done! We've sent a link to your Email 📨

How to define the target inventory level

Step 1. Know your demand

In developing an effective inventory strategy, it is essential to begin with the collection of data. This includes compiling a list of products utilized and each product's daily or weekly usage. Estimation of this usage can be accomplished by calculating the number of products used per service multiplied by the average number of services provided per week. For instance, if a hair salon uses half an ounce of shampoo per wash and performs ten washes daily, this translates to daily usage of five ounces.

However, for a more accurate measurement, I advise keeping records of each time a product is depleted. This practice will provide valuable insights that inform better decision-making. Here at Suplery, we adopt this stock-keeping method to make informed predictions of future demand.

Step 2. Define ordering frequency

The next step involves determining the ideal time between orders and order quantity. This analysis takes into account various factors, including internal business standards, supplier quantity discounts, minimum free-shipping amount, order processing costs, and daily product needs. Typically, the most popular products are ordered every 2-4 weeks. At the start, you can just pick up any frequency that allows you to minimize shipment costs and get quantity discounts.

Step 3. Calculate the target inventory level

With usage and ordering information, we can calculate the required inventory level to sustain operations between orders. In addition, to cater for unexpected events like increased demand or delivery delays, a safety stock amount must also be included. Together required inventory level and safety stock amount will be the target inventory level which, expressed in value this quantity, will show minimum inventory investment. Finally, the difference between the current stock value and minimal investment represents the hidden savings — funds that hat you can safely take out.

How to adjust product ordering

In order to reach your desired inventory levels, it is imperative to adjust your product ordering accordingly. This involves reducing the quantities of overstocked products, thereby decreasing the invoice total and freeing up funds.

A tricky thing in this process is the timing of reordering. Although it may appear logical to place an order when inventory levels reach the safety stock amount, the lead time for delivery must be taken into account. As we expect the order to arrive precisely when the inventory reaches the safety stock level, placing orders early enough to ensure timely delivery and maintain the target inventory level is advisable.

The most important thing here is to make this new inventory strategy a permanent fixture. It is essential to incorporate regularly reviewing the target inventory level, order quantities, and frequency into your daily operations. The use of software like Suplery can greatly assist in optimizing inventory levels and ensuring that orders are placed on time.

Moreover, data-driven analysis and continuous readjusting of inventory levels will allow keeping investment on a minimal sufficient level. So, you can maximize your return on investment (ROI) and ensure that your business operates as efficiently as possible. Whether you are just starting or looking to streamline your existing operations, these steps will help you get the most out of your inventory investment.

A practical example of calculating target inventory level and hidden savings

In this part, I will use the abovementioned theory to illustrate how the concept works.

Assuming a salon offers only one service, it uses 3 pieces of Product A and 5 pieces of Product B per service. Each pack of products A and B contains 50 pieces sold at $100 and $200 respectively. The salon currently has 15 packs of each product in its warehouse. The salon serves 25 customers per week and orders products every two weeks.

Here's how to calculate the target inventory level and hidden savings:

Step 1: Weekly usage

The salon uses 75 pieces of Product A and 125 pieces of Product B per week.

Step 2: Between order time

The salon orders product every two weeks.

Step 3: Operating quantity

To secure 2 weeks' worth of operation, the salon needs 150 pieces of Product A and 250 pieces of Product B.

Step 4: Safety stock amount

To account for fluctuations in demand and potential delayed deliveries, the salon needs a safety stock of 190 pieces of Product A and 315 pieces of Product B, or 2.5 weeks of operation.

Step 5: Target inventory level

The target inventory level is the sum of the operating quantity and safety stock, or 340 pieces of Product A and 565 pieces of Product B.

Step 6: Inventory investment and hidden savings

Each piece of Product A and B costs $2 and $4 respectively. So, the minimum inventory investment is $2x340+$4x565=$2,940. Currently, the salon keeps 15 packages of each product with a total value of $4,500. This results in hidden savings of $1,560, which is over 30% of the inventory value. My experience shows that is a quite common result. If fact, a salon can save 20% to 50% of inventory investment or from 4% to 10% of the overall monthly turnover simply by using efficient inventory strategies.

Calculate your inventory savings

Try our free inventory savings calculator and find out how much you can get

Start hereConclusions

In conclusion, managing inventory is crucial for beauty businesses to unlock hidden savings and maximize their return on investment (ROI). By collecting data on product usage and order frequency, determining the target inventory level, and adjusting product ordering, businesses can ensure their inventory strategy is proactive and data-driven. Incorporating regular reviews into daily operations and using software such as Suplery can help streamline inventory management and minimize investment while maintaining efficient operations. With these steps, companies can make the most of their inventory investment.

The latest articles and industry insights delivered to your inbox

The latest articles and industry insights delivered to your inbox

Subscribe to receive a monthly digest of our most valuable resources like blog posts, whitepapers, and guides.

Oh no! We couldn’t subscribe you ☹️

Done! You've subscribed 💛

Unsubscribe anytime. Your data is stored for business-to-business communication purposes. See our Privacy policy.

Last updated on Feb 21, 2023

“What Changed” in this article? Everything. It's packed with the latest findings, the ripest data, and a fresh analysis you won't find anywhere else.

A subject-matter expert wrote the content, and reliable, official sources support it. Recent research has been incorporated to maintain relevancy and accuracy.

Please share this post

Table of Contents

How to define the target inventory levelStep 1. Know your demandStep 2. Define ordering frequencyStep 3. Calculate the target inventory levelHow to adjust product orderingConclusionsCut inventory costs in salon: save on salon inventory & optimize stock

Unlock the secrets to slashing salon inventory costs! Boost profits by 10–15% with expert strategies and game-changing techniques to optimize stock and save thousands yearly.

Inventory management in beauty business

14 min

Building strong client relationships: from service to friendship

This article is a guide for salon owners who want to turn their clients into loyal fans. It goes beyond giving great service – it teaches you how to build relationships that keep people coming back.

Salon client management

5 min

Reducing salon costs: effective strategies for expense management

Struggling to manage salon expenses? This article breaks down simple ways to cut costs without sacrificing quality. Find tips you can actually use to keep your salon running smoothly and profitably.

Beauty salon operations & Team management

13 min

Unlock FREE bonus material!

Get your hands on "Weekly salon stock check: the ultimate PDF checklist". Subscribe to our newsletter and receive a link to download it straight to your inbox.

Oh no! We couldn’t subscribe you ☹️

Done! We've sent a link to your Email 📨

Trusted by the best in the beauty industry.

Transform your beauty business with Suplery!

Already enjoying our expert tips? Take the next step and join Suplery to revolutionize your business operations.

Huge range of professional products

One-click checkout after first order

Automated predictive orders

Seamless inventory management

From words to action

Start working with Suplery and explore all the tools and services you need to expand your business

Get started with Suplery24/7 Support

Secure payments

Designed by industry’s experts