Reorder point vs PAR level: the logic behind salon inventory control

Most beauty salons don’t run out of products by accident. They run out by guessing.

Guessing how much shampoo is “enough.” Guessing when to reorder. Guessing that one extra box on the shelf will somehow fix the problem.

The outcome is predictable. Either a service stops mid-day because something is missing — or cash sits frozen in backbar stock that doesn’t move.

Inventory chaos usually isn’t caused by bad suppliers or busy weeks. It’s caused by the absence of clear reorder logic. But no worries, this article fixes it.

📦 Reorder point vs PAR level: two numbers that power inventory control

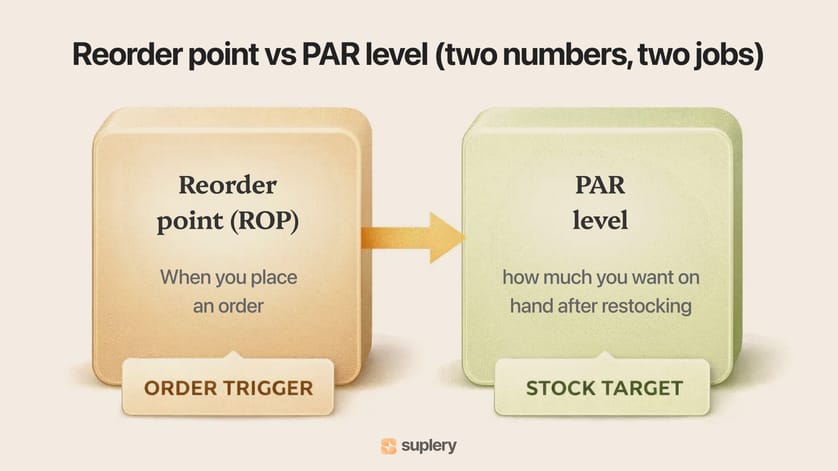

In salon inventory management systems, confusion usually starts with two numbers that sound similar but solve different tasks. Reorder point and PAR level are often treated as interchangeable, which weakens inventory control and makes stock decisions inconsistent.

⏰ Reorder point = when to reorder

The reorder point (ROP) is a trigger. It defines the exact stock level at which a new order should be placed. This number is built around real usage and time (not preference or habit).

A proper reorder point reflects:

- how fast the product is used

- how long delivery usually takes

- how much buffer is needed to absorb delays or spikes

When inventory reaches this level, action is required. The goal is continuity — ensuring the product lasts through the supplier’s lead time without service interruptions.

📊 PAR level = how much to restock

The PAR level defines the target amount of inventory you want to have on hand after restocking. It’s a quantity benchmark (not a timing signal).

PAR answers a different question:

- what stock level supports normal operations comfortably

- how much product should be available between deliveries

- how much inventory makes sense for this specific item

In practice, PAR is the level you replenish up to. If your PAR for a product is 10 units and current stock is 4, the reorder quantity is 6 units.

🔁 How the two work together

Reorder point and PAR level operate as a pair:

- Reorder point tells you when to place an order

- PAR level tells you how much inventory you want to end up with

Using one number for both roles blurs decision-making. Clear separation keeps ordering consistent and predictable — and stabilizes inventory levels across daily operations.

Salons that define both reorder points and PAR levels maintain healthier stock levels, improve inventory tracking, and avoid emergency orders, excess stock, and last-minute guesswork.

In simple terms:

- ROP protects timing

- PAR protects volume

Together, they form the foundation of controlled, repeatable inventory management.

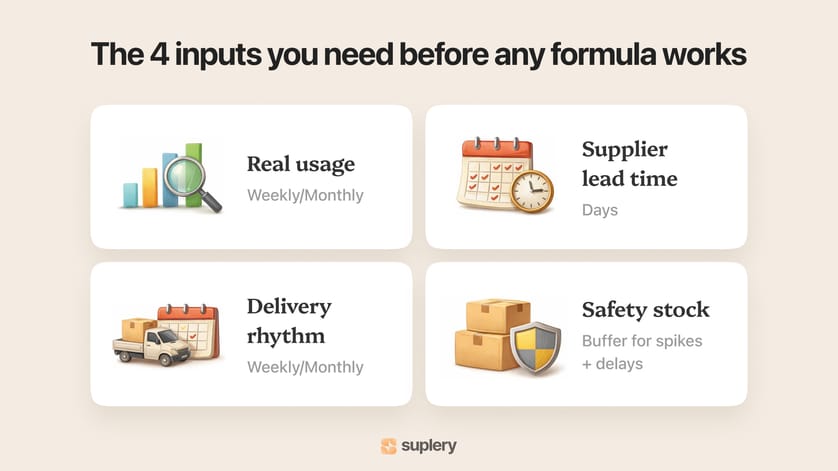

🔥 The numbers that actually run your inventory system

Reorder points and PAR levels only work when they’re built on real numbers. Before any formulas come into play, you need a small set of inputs that reflect how your salon actually operates.

This step is about replacing assumptions with measurable signals.

📉 1) Real product usage (what actually leaves the shelf)

Start with how much of each product you actually use over time. For salons, weekly or monthly usage is the most practical unit — daily can always be calculated later.

Usage can come from:

- service counts (how many services require this product)

- retail sales history

- backbar depletion over a defined period

For example, knowing that you go through 10 color tubes or 1.5 liters of shampoo per month gives you a baseline demand that everything else builds on. Without this number, reorder logic is guesswork.

🚚 2) Supplier lead time (how long reality takes)

Lead time is the gap between placing an order and receiving the product — an average based on past deliveries.

You’ll want to know:

- typical delivery time (in days)

- whether delays are common

- whether different brands have different lead times

This matters because inventory must last through this entire window. Any reorder point calculation that ignores lead time will fail the moment a shipment runs late.

📆 3) Delivery rhythm (how often stock can realistically move)

How often can you realistically restock?

Some salons order weekly. Others place one large monthly order. Some suppliers ship on fixed days only. This rhythm affects how much inventory you need to hold.

More frequent deliveries = lower required stock Less frequent deliveries = higher required stock

Delivery frequency directly influences PAR levels and determines how aggressively inventory can stay lean.

🛟 4) Safety stock (your built-in insurance)

Safety stock is your margin for error. It exists to absorb:

- demand spikes

- delayed shipments

- damaged or missing units

- sudden increases in bookings

This buffer can be:

- a fixed number of units

- a percentage of average usage

- a calculated worst-case reserve

Skipping safety stock means every disruption turns into a crisis. Oversizing it turns inventory into dead capital. The balance comes from observing how often you actually dip into that buffer.

When these four data points are defined, reorder logic becomes predictable instead of reactive. Inventory decisions stop being emotional (“we’re almost out”) and start being procedural (“this hit its trigger”).

Download your smart backbar toolkit

Ready-to-print templates to track product opening, measure doses, log leftovers, and cut backbar waste. Download now and run your inventory smarter.

Oh no! We couldn’t subscribe you ☹️

Done! We've sent a link to your Email ��📨

🧮 The reorder point formula that keeps shelves calm

Once usage, lead time, delivery rhythm, and safety stock are clear, the reorder point becomes straightforward. The goal is to define the exact moment when an order must be placed so inventory lasts through delivery without disruption.

🧠 The one formula that matters

Reorder Point (ROP) = (Average daily usage × Lead time in days) + Safety stock

This formula answers one question only: How much will you use before the next delivery arrives — plus a buffer?

🔍 How to read it in plain language

- Average daily usage How fast the product moves on a normal day. If you track weekly or monthly usage, convert it to daily.

- Lead time The number of days between placing an order and receiving it.

- Safety stock Extra units held to absorb delays, spikes, or unexpected demand.

When on-hand inventory hits this number, it’s time to reorder. Not sooner. Not later.

⚡ Example: a fast-moving backbar product

Let’s say:

- You use 1 liter of shampoo per week

- Supplier lead time is 14 days

- You want 1 liter as safety stock

Convert usage to daily: 1 liter ÷ 7 days ≈ 0.14 liters/day

Now calculate:

- Lead-time usage: 0.14 × 14 ≈ 2 liters

- Add safety stock: 2 + 1 = 3 liters

Reorder point = 3 liters

That means when your backbar drops to 3 liters, you place an order. Those 3 liters will carry you through delivery, with a cushion left if anything shifts.

🛟 Choosing safety stock without overdoing it

There are two practical approaches:

- Rule of thumb: Keep 20–25% of average usage as safety stock for stable products.

- Variability-based: Increase the buffer for products with unpredictable demand or inconsistent delivery. Reduce it for slow, predictable items.

Safety stock isn’t static. Adjust it based on how often you actually rely on it.

📦 How to set PAR levels for salon products

If reorder point defines when to act, PAR level defines how much inventory should feel comfortable. PAR is not a single rule applied everywhere — it changes by product role, cost, and usage speed. The goal is to set a level that supports service continuity without locking cash on the shelf.

🚿1) Daily-use backbar (high-turnover items)

These are shampoos, conditioners, developers, core color shades, and cleansers used in most services. Running out interrupts revenue immediately, so PAR should reflect steady flow.

How to set PAR:

- Base it on one delivery cycle of usage

- Add a small buffer for fluctuations

Example: If you use 10 units per week and restock weekly, PAR = 12 units. Each reorder brings inventory back to that level.

Why it works: High-turnover items earn their space. A slightly higher PAR protects service flow and reduces emergency orders.

💎2) High-cost or slow-moving products

This includes luxury treatments, specialty ampoules, niche shades, or items used occasionally. These products tie up capital quickly.

How to set PAR:

- Keep one cycle of expected use

- Minimize buffer

- Consider order-on-demand for very slow movers

Example: If you perform ~5 treatments per month, PAR = 5 units (or even 2–3 if lead time is short).

Why it works: Lower PAR prevents dead stock and expiry while still covering known demand.

🧤3) Consumables and single-use supplies

Gloves, foils, cotton pads, wax sticks, disposables — low cost, high necessity, zero tolerance for shortages.

How to set PAR:

- Base it on multiple weeks or months of usage

- Prioritize availability over tight optimization

Example: If you use 400 gloves per month, PAR = 800–1,000 gloves.

Why it works: The cost of holding extra is low. The cost of running out is operational shutdown.

🧠 Adjusting PAR as the salon evolves

PAR levels aren’t fixed. Review them when:

- service mix changes

- seasonality shifts demand

- supplier lead times change

- products consistently sit unused or sell faster than expected

A stable PAR adapts with the business, not against it.

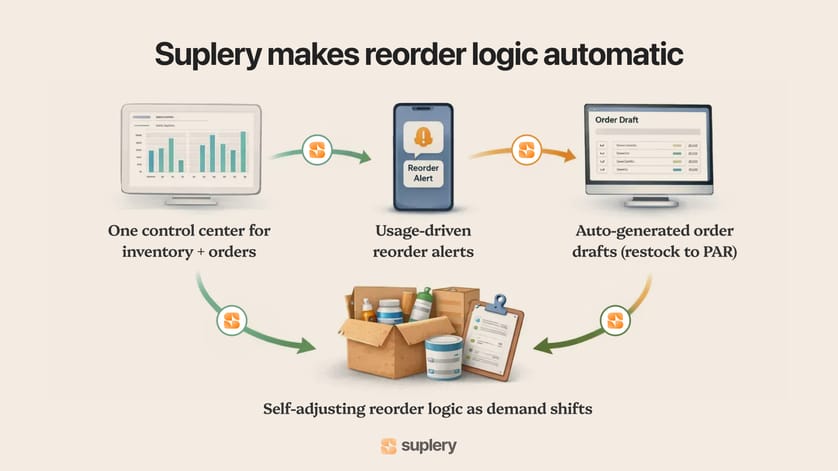

⚙️ How to keep reorder logic working — without manual effort

Reorder points and PAR levels only work if they’re followed consistently.

The moment tracking inventory depends on memory, spreadsheets, or someone remembering to “check stock later,” the inventory management system starts to fail — because salons don’t run on spare attention or extra time.

First step is setting the rules. But the real task is making sure the rules are applied every day.

This is where you need Suplery.

🔍 What Suplery does in the background

Suplery combines a professional beauty marketplace with a built-in inventory management system. You buy products from brands you trust, and Suplery tracks usage, stock levels, and reorders automatically — without extra software or setup.

Here’s how that plays out day to day:

- 📦 Usage-driven reorder alerts Alerts trigger based on real consumption patterns and supplier lead times, preventing stockouts without forcing overstock. No spreadsheets. No mental notes.

- 🧾 Auto-generated order drafts

Orders are prepared automatically to restore products back to PAR, using:

- current stock levels

- historical usage

- upcoming demand signals You review and approve — Suplery handles the math.

- 🔄 Self-adjusting reorder logic

As demand shifts or seasonality kicks in:

- fast-moving products surface earlier

- slow movers stop draining budget

- ordering stays accurate without manual recalibration

- 🧠 One unified control center Inventory, suppliers, orders, and communications stay centralized — across brands, teams, and locations — eliminating scattered systems and duplicated effort.

🧘♀️ What this changes for owners and managers

When inventory logic runs continuously:

- decisions stop piling up

- errors and last-minute scrambling drop

- ordering becomes predictable instead of reactive

- confidence replaces constant checking

Inventory turns into infrastructure — something you rely on.

🧡 Ready to let Suplery do the heavy lifting?

If you want reorder points and PAR levels that actually hold under real operating pressure, register on Suplery and move inventory decisions into a system built for scale.

The latest articles and industry insights delivered to your inbox

The latest articles and industry insights delivered to your inbox

Subscribe to receive a monthly digest of our most valuable resources like blog posts, whitepapers, and guides.

Oh no! We couldn’t subscribe you ☹️

Done! You've subscribed 💛

Unsubscribe anytime. Your data is stored for business-to-business communication purposes. See our Privacy policy.

Frequently asked questions

What is salon inventory management and why does it matter?

Salon inventory management is the process of tracking, controlling, and replenishing products used in beauty services and retail sales. It covers backbar products, retail inventory, consumables, and supplies needed for daily operations. Proper inventory management helps salon owners avoid running out of products, reduce waste, control carrying costs, and maintain smooth salon operations without freezing cash in excess stock.

How is salon inventory management different from spa inventory or bar inventory?

Salon inventory management focuses heavily on high-usage beauty products like hair color, developers, shampoos, and styling products, while spa inventory often includes treatment kits, single-use items, and lower turnover SKUs. Bar inventory emphasizes portion control and alcohol tracking, whereas salon inventory must account for expiration dates, color cost, client appointments, and product-specific usage patterns.

What is the difference between an inventory management system and inventory management software?

An inventory management system refers to the full process — rules, reorder points, PAR levels, audits, and supplier relationships. Inventory management software is the tool that supports that system by tracking inventory records, stock levels, purchase orders, and inventory turnover automatically. For salons, the best solution combines both — clear logic plus software that applies it consistently.

How does salon inventory management software help salon owners?

Salon inventory management software helps by:

- tracking inventory levels in real time

- monitoring slow moving products

- generating purchase orders automatically

- reducing time-consuming manual tracking

- supporting multiple locations from one screen

This allows salon owners to focus on customer satisfaction, services, and growth instead of constant stock checking.

What is inventory tracking and why is it important?

Inventory tracking is the process of keeping an accurate track of how much product enters and leaves your salon. It prevents over-ordering, highlights product waste, improves inventory control, and ensures you always have enough inventory to support booked client appointments.

How do reorder points work in inventory management?

Reorder points define when a salon should place a new order based on usage, lead time, and safety stock. When inventory hits the reorder point, an order is triggered to prevent stockouts while avoiding excess inventory. Establishing reorder points removes guessing and keeps stock levels predictable.

What is a PAR level in salon inventory?

PAR level defines how much inventory you want to have after restocking. It supports stable daily operations by ensuring enough product is available between deliveries without increasing carrying costs unnecessarily.

How do reorder points and PAR levels work together?

Reorder points answer when to reorder. PAR levels answer how much to restock. Together, they create effective inventory management processes that reduce waste, stabilize stock levels, and eliminate emergency orders.

What causes inventory waste in beauty salons?

Common causes of product waste include:

- ordering without tracking real usage

- ignoring expiration dates

- holding slow moving products at high PAR levels

- lack of regular audits

- poor inventory records

Minimizing waste starts with accurate tracking and clearly defined reorder logic.

How do salons manage inventory across multiple locations?

Managing salon inventory across multiple locations requires centralized inventory control. A unified system allows owners to:

- monitor stock levels per location

- balance inventory between salons

- standardize reorder points and PAR levels

- improve vendor relationships

This prevents overstock in one location and shortages in another.

How does inventory management affect customer satisfaction?

When inventory is managed properly:

- services are never interrupted

- preferred products are always available

- retail products stay in stock

- bookings run smoothly

This directly improves customer satisfaction and trust in the salon’s professionalism.

What role do POS systems play in salon inventory management?

A salon POS system can support inventory tracking by recording product sales and service usage. When integrated with inventory management software, POS data helps identify sales trends, customer demand, and inventory needs more accurately.

How often should salons review inventory levels?

Most beauty businesses should regularly review inventory:

- weekly for fast-moving backbar products

- monthly for retail inventory

- quarterly for slow moving or high-cost items

Regular audits help maintain accurate stock levels and prevent waste.

How does inventory management help reduce costs?

Effective inventory management helps reduce costs by:

- lowering carrying costs

- minimizing expired and unused products

- preventing over-ordering

- improving pricing decisions

- reducing emergency shipping fees

Over time, this leads to higher margins and increased profits.

Is barcode scanning necessary for salon inventory?

Barcode scanning isn’t mandatory, but it improves accuracy and saves time. It reduces human error, supports faster tracking, and helps maintain accurate inventory records, especially for salons with large product catalogs.

How much training does salon inventory software require?

Modern salon inventory management software is designed for minimal training. Most systems work in just a few clicks, allowing teams to manage inventory from the same screen they already use for orders and daily operations.

How does inventory turnover affect salon performance?

Inventory turnover measures how quickly products move through your salon. Healthy turnover means:

- less cash tied in stock

- fewer expired products

- better alignment with customer demand

Low turnover signals slow moving products that may need lower PAR levels or removal.

Can inventory management software replace spreadsheets?

Yes. Inventory software eliminates manual spreadsheets by automating tracking, reorder alerts, and purchase orders. This improves accuracy, saves time, and ensures inventory decisions are based on real data instead of assumptions.

How does Suplery support salon inventory management?

Suplery combines a professional beauty marketplace with built-in inventory management tools. It helps salons:

- track inventory automatically

- establish reorder points and PAR levels

- generate purchase orders

- manage inventory across multiple locations

- reduce waste and save time

All without adding extra software or manual processes.

Last updated on Feb 09, 2026

This is a new article explaining the difference between reorder point and PAR level, showing how the two numbers work together to create predictable, system-based salon inventory control.

Institute for Supply Management (ISM) — “Reorder Point Formula with Practical Examples”

Oracle NetSuite — “Reorder Point Defined: Formula & How to Use”

ASCM / APICS Magazine — “Understanding safety stock and mastering its equations” (PDF)

MIT OpenCourseWare (MIT CTL) — “Inventory Management” Lecture Slides (PDF)

Oracle Cloud SCM Docs — “Overview of PAR Replenishment”

Georgia Tech ISyE — ��“Logistics Systems Design: Inventory Systems” (PDF)

Please share this post

Table of Contents

📦 Reorder point vs PAR level: two numbers that power inventory control🔥 The numbers that actually run your inventory system🧮 The reorder point formula that keeps shelves calm📦 How to set PAR levels for salon products ⚙️ How to keep reorder logic working — without manual effortFrequently asked questionsInventory control differences across salons, spas, and barbershops

Inventory control isn’t glamorous, but it makes or breaks beauty businesses. This article reveals the differences in salon, spa, nail, barbershop, and medspa inventory management — and shows how to cut waste while boosting profit.

Inventory management in beauty business

10 min

Beauty salon backbar waste: how to reduce and save money

Over-pouring, open bottles, and leftovers add up fast. Discover how to stop backbar waste in your salon with simple fixes your team will actually use.

Inventory management in beauty business

9 min

From stock chaos to profit: 6 salon inventory case studies

See how top salons streamlined inventory, slashed costs, and grew profits. Steal these proven strategies and turn your stockroom into a secret profit weapon.

Inventory management in beauty business

8 min

Unlock FREE bonus material!

Get your hands on "Your loyalty checklist: 6 secrets to keep clients coming back". Subscribe to our newsletter and receive a link to download it straight to your inbox.

Oh no! We couldn’t subscribe you ☹️

Done! We've sent a link to your Email 📨

Trusted by the best in the beauty industry.

Transform your beauty business with Suplery!

Already enjoying our expert tips? Take the next step and join Suplery to revolutionize your business operations.

Huge range of professional products

One-click checkout after first order

Automated predictive orders

Seamless inventory management

From words to action

Start working with Suplery and explore all the tools and services you need to expand your business

Get started with Suplery24/7 Support

Secure payments

Designed by industry’s experts